- Index

- Bearing Type

- Carburant

- Code Moteur

- Cooling Type

- Fabricant

- Aftermarket (19)

- Audi (28)

- Auto Pièces-pro (13)

- Bmt (12)

- Borgwarner (38)

- Ebc Freins Allemagne (15)

- Eps-allemagne (31)

- Fabricant D'origine (18)

- Fox Épuiser (19)

- Garrett (64)

- Ihi (33)

- Kkk (20)

- Mhi (13)

- Nissens (20)

- Pas Pertinent (85)

- Q1-part (53)

- Seat (16)

- Team2fast Gmbh (13)

- Volkswagen (36)

- X-parts (18)

- ... (3605)

- Type De Produit

- Chargeur, Chargement (2)

- Conversion Du Moteur (2)

- Descente (2)

- Durite Entrée D'air (3)

- Groupe Central Chra (4)

- Groupe Croupe Chra (4)

- Groupe Tronqué (2)

- Lader (3)

- Moteur (13)

- Non EnchaÎnÉ (2)

- Silencieux Sport (22)

- Suralimentation (6)

- Tubulure Décart (2)

- Turbo (284)

- Turbo Tuyau (2)

- Turbo-collecteur (6)

- Turbocompresseur (25)

- Turbokit (7)

- Vanne Egr (22)

- Voir / Instruments (2)

- ... (3754)

713672-5006S Turbo complet 038253019CX 454232-1 for Seat Leon 1.9 TDI 92/110 CV

RIXturbo, was established in 2008, is a high-tech enterprise in full turbocharger industry chain, Locating in Shenyang Liaoning. The company has developed series of turbochargers which meet the requirement of diesel, gasoline, internal combustion. The company strives to improve and utilize its sales network, using diversified sales methods including attending various exhibitions to promote the advantages of our products.

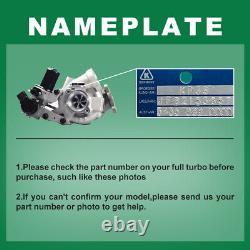

The company uses ZEISS 3D coordinate measurement machine, HOMMEL roundness tester and optical scanner, contour and roughness meter for component durability. Our company uses SCHENCK and TURBOTECHNIC VSR 400 balancing machine. We use Chiron and DMG 5-axis produce Billet/MFS compressor wheel. We have over 50,000 pcs cartridge and turbos in stock. Veuillez confirmer le numéro de pièce sur votre ancienne plaque de turbocompresseur avant de commander.

038253019C, 038253019CX, 038253019CV, 038253019A, 038253019AX, 038253019AV, 03G253014R, 03G253016K. Step 1: Before Replacing A Turbo. It is important to conduct a thorough diagnostic check of the engine system to determine if the "fault" is actually the turbocharger. A lack of power, noisy operation, excessive smoke or oil consumption could result from a faulty fuel injection system, ECU or electrical problems, restricted or blocked air filter, a amaged exhaust system or a lubrication problem.

A higher than normal crankcase pressure reading may lead to oil leakage from the turbo into the inlet and exhaust systems. Step 2: Before Replacing A Turbo. If the engine diagnostic check does not uncover any obvious cause, make sure that an extensive trouble shooting analysis is completed.

Key turbocharger areas for examination include foreign objects, lack of lubrication, oil contamination, over-speeding of the turbo and excessive temperature. This is important because turbo damage can often be a symptom of an underlying problem rather than the cause itself. The following steps must be strictly followed. Always consult the workshop manual for instructions which are specific to your engine or vehicle. Check the part number to ensure that it is the right one for the engine.It is important that during the whole installation process, you prevent dirt or debris from entering any part of the turbo. Any dirt or debris entering the turbo may cause catastrophic damage due to the very high speed of operation (up to 300,000rpm). Ensure that correct gaskets are used. For example - the center hole of any gasket must be perfectly aligned with the center hole of the turbo flange.

Some turbos use a threaded connector and no gasket. Some turbos use a "banjo fitting" with "banjo bolt"; in these cases, use new sealing gaskets/washers. Important Note: Do not use liquid gasket or sealants, particularly for the oil inlet or outlet since excessive material may enter the turbo, reducing or stopping oil flow. It is recommended that you use new air, oil and fuel filters and clean engine oil to the engine or vehicle maker's specification.

When installing the new oil filter, if possible, fill it with clean, fresh engine oil. Also, if it is accessible, back-fill the pressure line from the oil pump to the filter. This is particularly important on high mileage engines, where the oil pressure line may empty during oil changes!

Before installing the turbo, ensure that all air hoses connected to the turbo are totally clean and show no sign of any damage. The air filter and its housing must be completely clean and free from any debris. Clean the engine breather system (Positive Crankcase Ventilation system) and ensure that it functions properly. Any blockages or malfunction may cause high crankcase pressure and lead to oil leakage from the turbo into the inlet and exhaust systems. Remove any old gasket material from the exhaust manifold and pipe.

The surfaces of the flange must be clean and have no damage. Then remove plastic or foam blanking plugs from the turbo. Position the turbo onto manifold or engine block using the correct new gasket or O ring, and then reconnect the exhaust pipe.

Tighten all nuts and bolts. Important Note for Steps 12-15 Pay special attention to oil feed and drain lines, which must be totally clean and have no damage to ensure unrestricted oil flow.

Make sure that flexible hose liners have not collapsed internally and that the oil feed line is not too close to source of heat which may have damaged the oil feed line internally. This is common on some vehicles and difficult to detect without cutting the pipe! For this reason, we recommend fitting a new oil inlet pipe when installing the new turbo. Next, install oil drain line to the turbocharger. Pour new engine oil into the oil inlet hole of the turbocharger. Next, fit the new oil feed line. Install inlet and outlet air hoses to turbocharger compressor housing. Make sure that the connections are airtight and hose clamps are correctly tightened.Crank the engine for 10 - 15 seconds without starting the engine. If possible, disable the fuelling/ignition or use compression test mode to allow this.

This helps to prime the oil feed to the turbocharger by filling the oil pressure lines, oil filter and turbo with oil before start-up. Important Note: As soon as the engine starts, the turbo will run at high speed and a lack of lubrication in these vital first few seconds can destroy a brand new turbo.

Then start the engine, and let it idle for 3 to 4 minutes to allow for proper inspection of oil, gas and air leakage. If any leakage is detected during engine start up, fix the issue immediately.

Stop the engine and re-check engine oil level. Oil level should be between the minimum and maximum mark on the dipstick - it is important to make sure that oil level is not above the point where turbo oil drain pipe connects to the engine or this may lead to oil leakage from the turbo into the inlet and exhaust systems. Cet item est dans la catégorie "Auto, moto - pièces, accessoires\Automobile : pièces et accessoires\Système d'admission moteur\Turbos, compresseurs et ETI\Turbos et pièces". Le vendeur est "turbo_rio" et est localisé dans ce pays: FR. Cet article peut être expédié au pays suivant: Union européenne.

- Couleur: Doré

- Marque: Rix Turbo

- Autre numéro de pièce: 713672, 713672-5006S, 713672-9006S, 713672-5005S, 768329-5001S, 454232-0001, 454232-0003, 454232-0004, 454232-0005, 454232-1, 454232-3, 454232-4, 454232-5, 768331-0001, 768331-0002, 713672-0001, 713672-0002, 713672-0003, 713672-0004, 713672-0005, 713672-0006

- Numéro de référence OE/OEM: 038253019C, 038253019CX, 038253019CV, 038253019A, 038253019AX, 038253019AV, 03G253014R, 03G253016K

- Pays de fabrication: Chine

- Placement: Arrière

- Numéro de pièce fabricant: 713672

- Modèle: GT1749V

- Emplacement sur le véhicule: Avant

- Garantie fabricant: 2 ans